Effective reagent management in 5 steps

In this blog post, we briefly outline the importance of reagent management in pharmaceutical QC labs and explore 5 key steps you can take to more effectively manage the inventory of consumables in your lab, saving time and relieving budgetary pressure.

In a rush? Here are the 3 key takeaways

- 👉 Maintaining working stocks of reagents and other chemical or biological consumables is business critical; overstocking can be expensive and wasteful but is seen as a necessary evil to avoid supply shortfalls

- 👉 Effectively managing reagents is challenging and involves making an accurate inventory, forecasting consumption rates, determining optimal replenishment dates, allowing sufficient time for material qualification, and ensuring the capacity exists for those qualification activities

- 👉 Binocs includes reagent management features that allow the end-to-end process to be handled automatically, based on configurable parameters that can be fully customized to your lab’s specific requirements

In recent years, pharmaceutical laboratories have been under more and more pressure. Budgets are subject to ever-growing constraints and labs are expected to do more with less. As such, lab managers find themselves on an unending quest to identify and implement new opportunities to refine processes and streamline operations in an effort to control costs and eliminate waste. Consumables, such as reagents, are a significant part of the lab’s budget and represent significant potential for cost savings.

Why effective reagent management matters

Reagents (solvents, reference standard material, and other chemical or biological solutions) must be kept readily available and accessible in the lab’s inventory so that they can be used in a range of test methods. Such substances vary significantly in their respective storage conditions and shelf life, and may be consumed in very different volumes and at different frequencies; each unit in stock takes up limited space, meaning that simply storing them can accrue additional costs (e.g. if it needs to be refrigerated or climate-controlled in some other way).

Effective inventory management for such consumables therefore means ensuring that the stock is sufficient to meet the need on an ongoing basis but without storing more material than is necessary at any given moment (and thus risking expiry).

To effectively manage these materials, it is necessary to accurately forecast consumption—that is, know in advance which analyses will be performed and thus estimate how much of each reagent will be consumed in delivering those analyses in the coming weeks and months. By comparing expected future demand against known stock quantities, labs can (in principle) limit their inventory expenditure and minimize wastage, making this process critical to running a productive laboratory.

Getting reagent management right

Many labs may still choose to manage their inventory using pen and paper or basic spreadsheets, however, with increasing digitalization and a growing move towards paperless practices, smarter methods are required. Smarter, though, doesn’t need to mean more complicated or time-consuming—indeed, using the best tools and doing the job right on the first go can quickly result in quantifiable time and budgetary gains.

So, what does “smarter” look like? Let’s keep it simple.

A system of effective reagent management needs to intelligently balance several realities and meet specific requirements:

- Reagents are business-critical: reagents need to be on hand whenever your analysts need them, otherwise, they can’t execute their work.

- Requirement: avoid reagent non-availability or stock-out, no exceptions.

- Holding reagents in stock costs money: reagents take up limited space, can require refrigeration and can expire while still in storage.

- Requirement: minimize excess inventory and use materials within their shelf life to avoid wastage.

- Restocking reagents takes time: it’s not practical (or even always possible) to spontaneously order more reagents when you see you are running out—they require production, bridging, and validation, which all contribute to long lead times.

- Requirement: plan well ahead to ensure there is no shortfall of critical consumables.

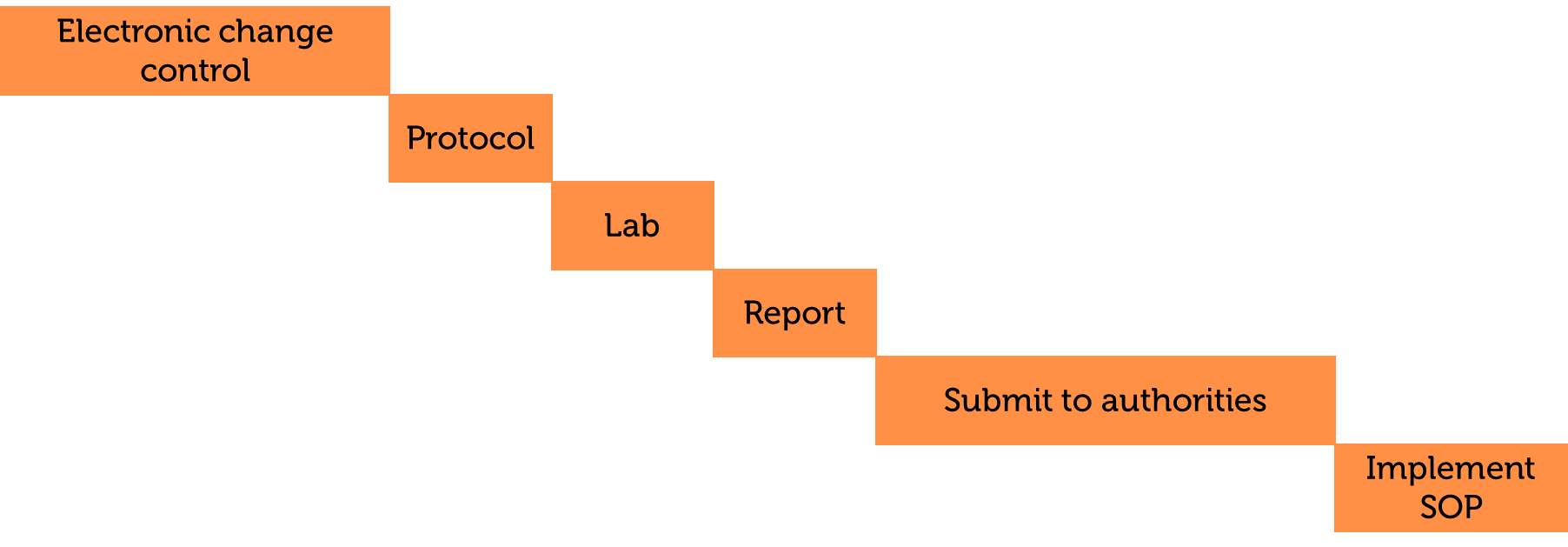

- Qualifying reagents requires time and resources: the process of qualifying standard reference material (for instance) can take up to a year and involve multiple steps executed by different individuals.

- Requirement: prioritize such activities to ensure there is sufficient capacity for qualifying materials by the time they are needed.

Manually balancing these realities is a significant challenge because:

- The top priority is ensuring that reagents are available when your analysts need them, however, lab demand is volatile, which makes restock requirements unpredictable. This unpredictability is every lab’s Achilles heel so, to avoid risking successful delivery due to missing reagents, they traditionally have no choice but to overstock. In the war between productivity and inefficiency, avoidable wastage will always be the lesser of two evils.

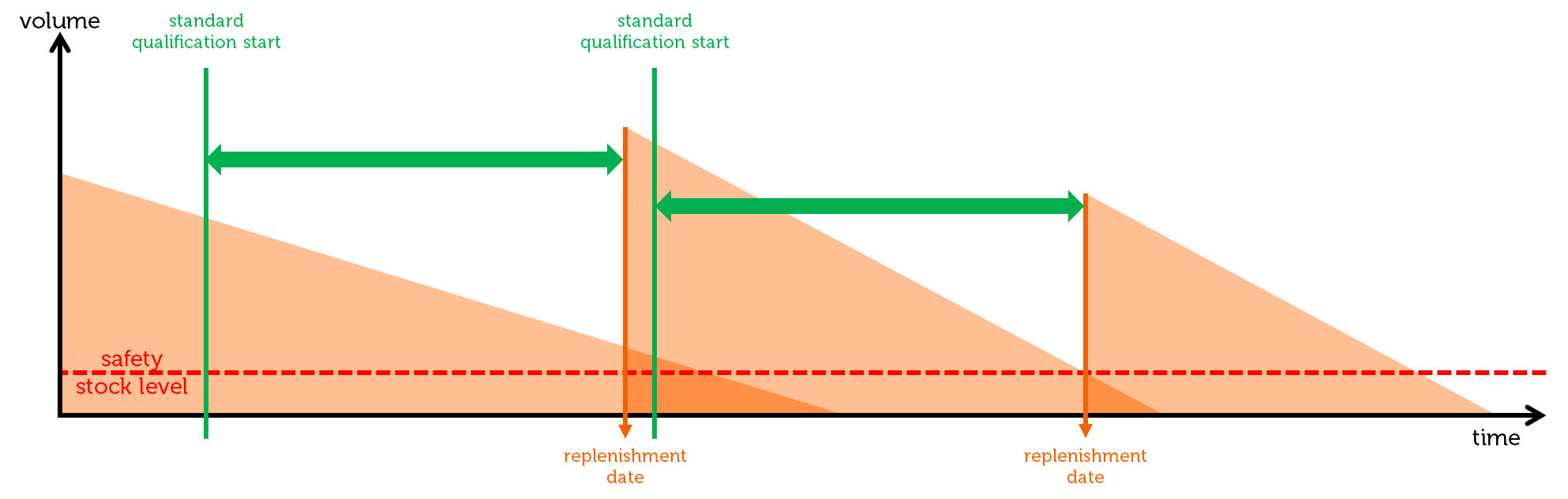

- Without a systematic way of forecasting and tracking demand (and thus reagent consumption), it can be almost impossible to determine the optimal replenishment date that will avoid hitting the expiration date or safety stock.

- Without visibility of the lab’s mid-to-long term capacity, there can be little guarantee that there will be the necessary resources for timely reagent qualification.

Effective reagent management: 5 steps

So, how can you immediately establish an effective system for optimizing your reagents inventory management? These five steps, although simplified, might be a good start:

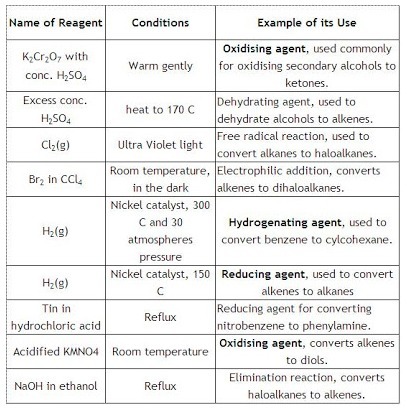

- Step 1: make an accurate inventory of your existing stock (and note the expiry dates)

- Step 2: use expected demand to forecast your reagent consumption rate (predicting the downward slope)

- Step 3: calculate your optimal replenishment dates (taking into account expiration dates and safety stock)

- Step 4: calculate the latest date by which you need to start the material qualification (to ensure it’s available when the lab needs it)

- Step 5: ensure you have sufficient capacity to deliver qualification activities (based on the availability of appropriately qualified personnel and instruments)

Reagent management: how Binocs can help

Sounds pretty straightforward, right? Unfortunately, the reality is that each of these steps needs to be repeated for every reagent product and maintained on an ongoing basis. Managing this process manually can be overwhelming and a significant time sink.

Luckily, however, Binocs is here to help you get it right:

- Binocs uses its insight into your lab’s upcoming demand to help you accurately forecast reagent consumption (forecast the downward slope). This gives you full visibility on:

- Historical data (e.g., “runners”, predictable volumes)

- NPI forecasts (new product introductions)

- Programs (committed volumes/time).

- Binocs will automatically calculate your optimal replenishment dates for you, effortlessly accommodating your safety stock and expiration date requirements

- This calculation is based on fully configurable parameters, meaning that, once it is set up, the output will consistently match your lab’s defined inventory strategy

- Binocs will automatically create a detailed sequence of activities that the lab must execute in order to qualify the material. Example below:

- The Binocs planning algorithm constantly monitors your resource availability (appropriately trained analysts and suitable equipment) to accurately forecast whether you’ll have sufficient capacity to qualify the material in time

- If bottlenecks are identified, you can use what-if scenarios to solve capacity issues before they even happen

How do you manage reagent inventories in your lab? We’re curious to know more about what challenges you face and would welcome the opportunity to discuss how we can help! Book your discovery meeting below!