How We Plan Technician Capacity for Release Testing (Using the Binocs API)

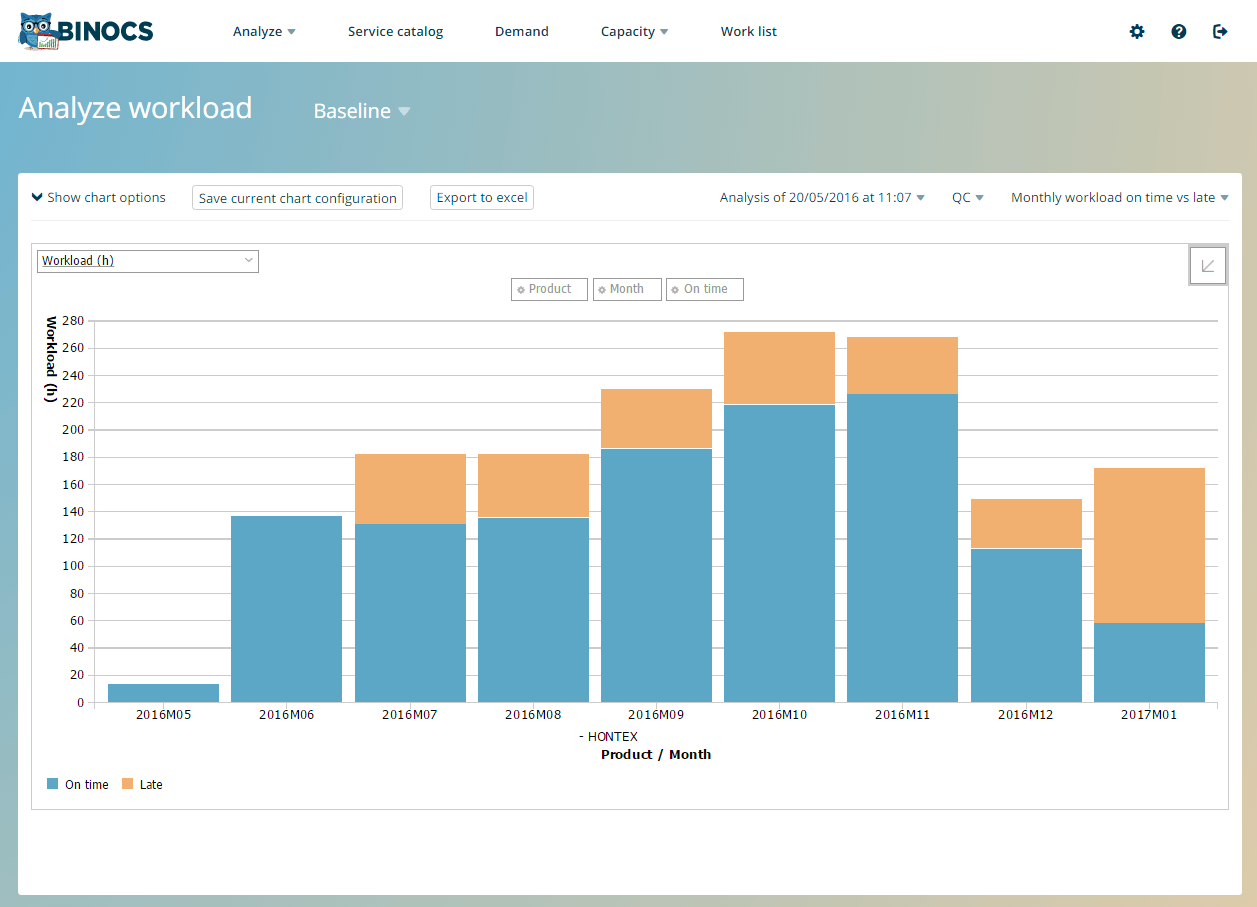

Pharmaceutical products need to be analyzed quickly, accurately and in a timely manner before they are released and distributed to the commercial marketplace (= release testing). Timely is the key word. If releases are slowed down, money is lost. Lab supervisors, responsible for the analyses, want to know whether they will be able to cope with the workload the technician resource planning for release will bring, so they can to proactively act on capacity problems solving far before they cause last-minute staffing changes, extra shifts, hiring of interim workers – or worst of all, delivering late. Binocs can help. For this, Binocs needs the QC samples demanded of each lab team. In other words, we want to translate the commercial forecast into QC samples – of course, whilst avoiding manual input, especially if a part of the input is already in other systems. So we developed a Binocs Excel add-on, which is used by some of our QC lab clients.

Technician resource planning for release

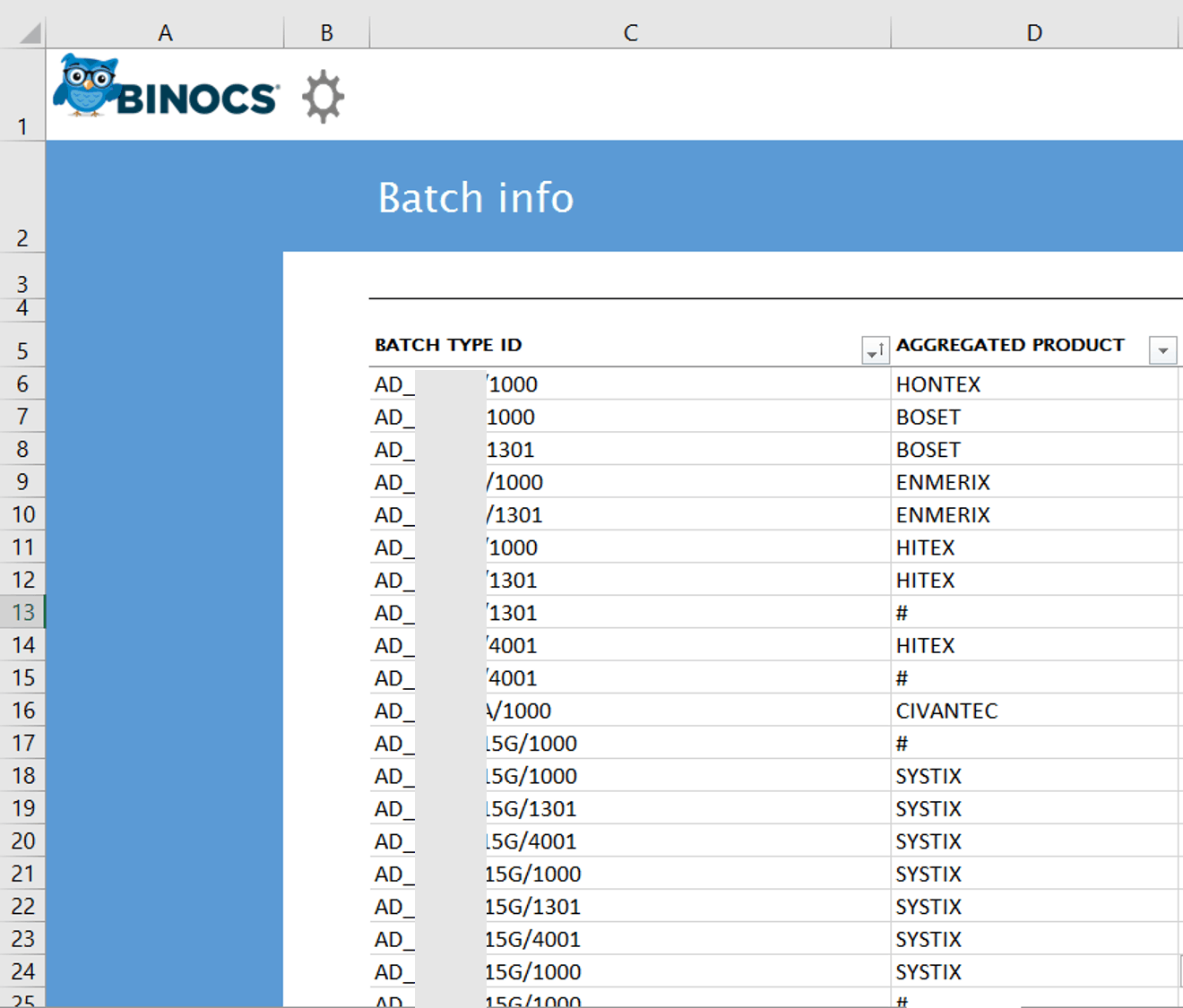

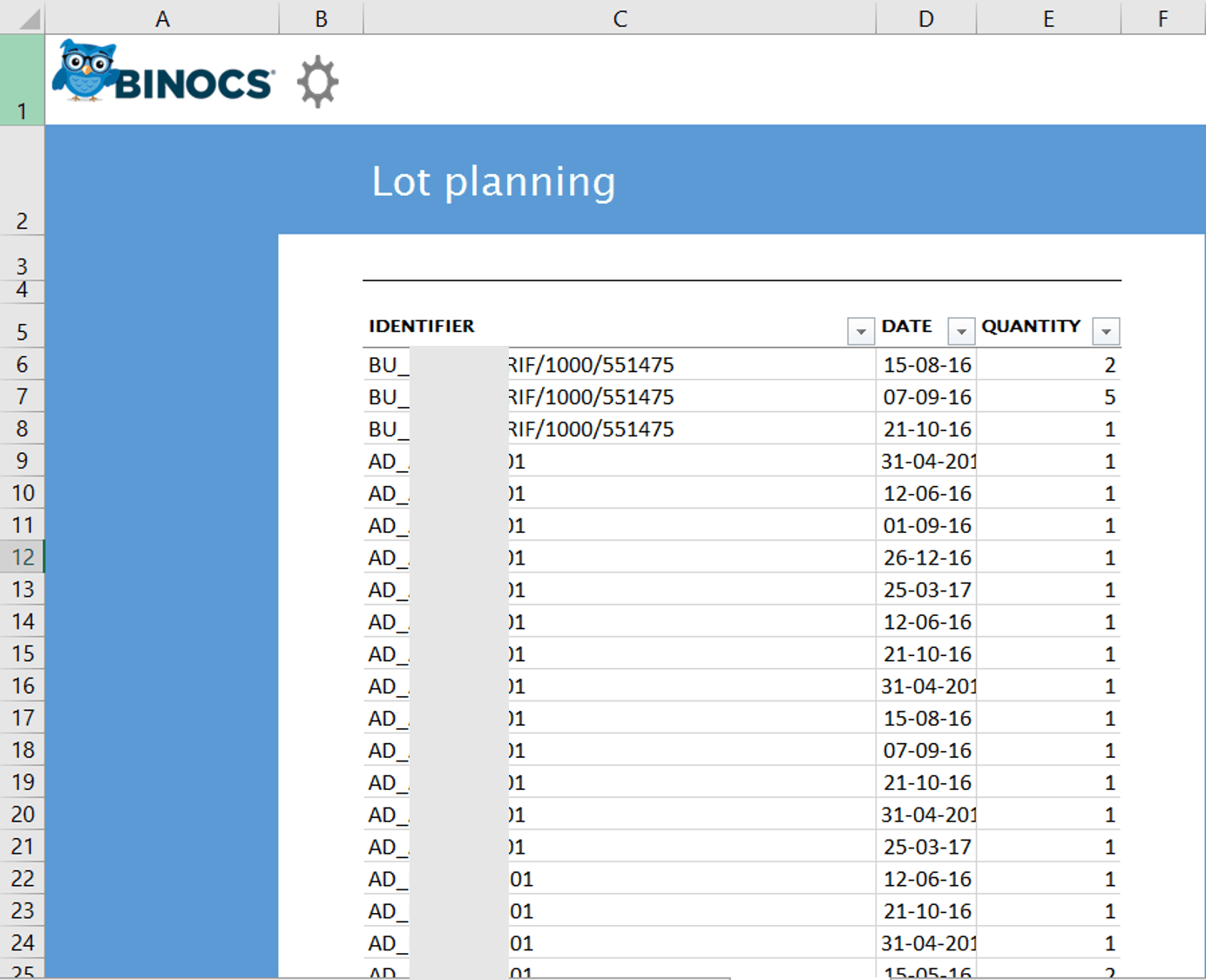

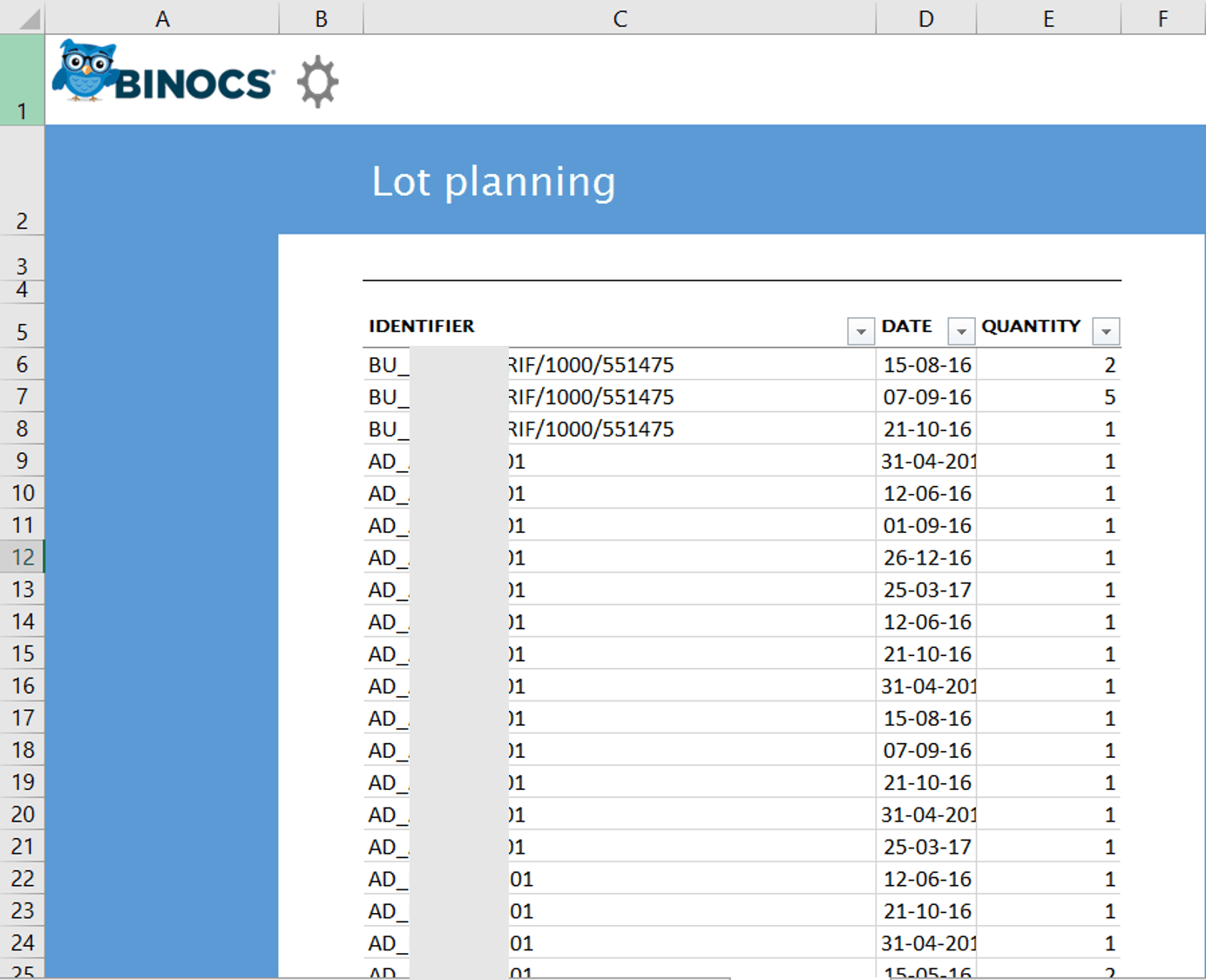

The ERP system contains production plans for each product indicating the number of batches that will be produced in the coming months. An extract is entered into the Excel add-on.

:

- For “runners” (high volume products) we use historical data.

- For “strangers” (ad hoc production, low volumes) we use specific calculation rules.

Inspection plans provide details about what tests need to be performed in order to ensure the quality of the product. The test plans are managed in the Excel add-on.

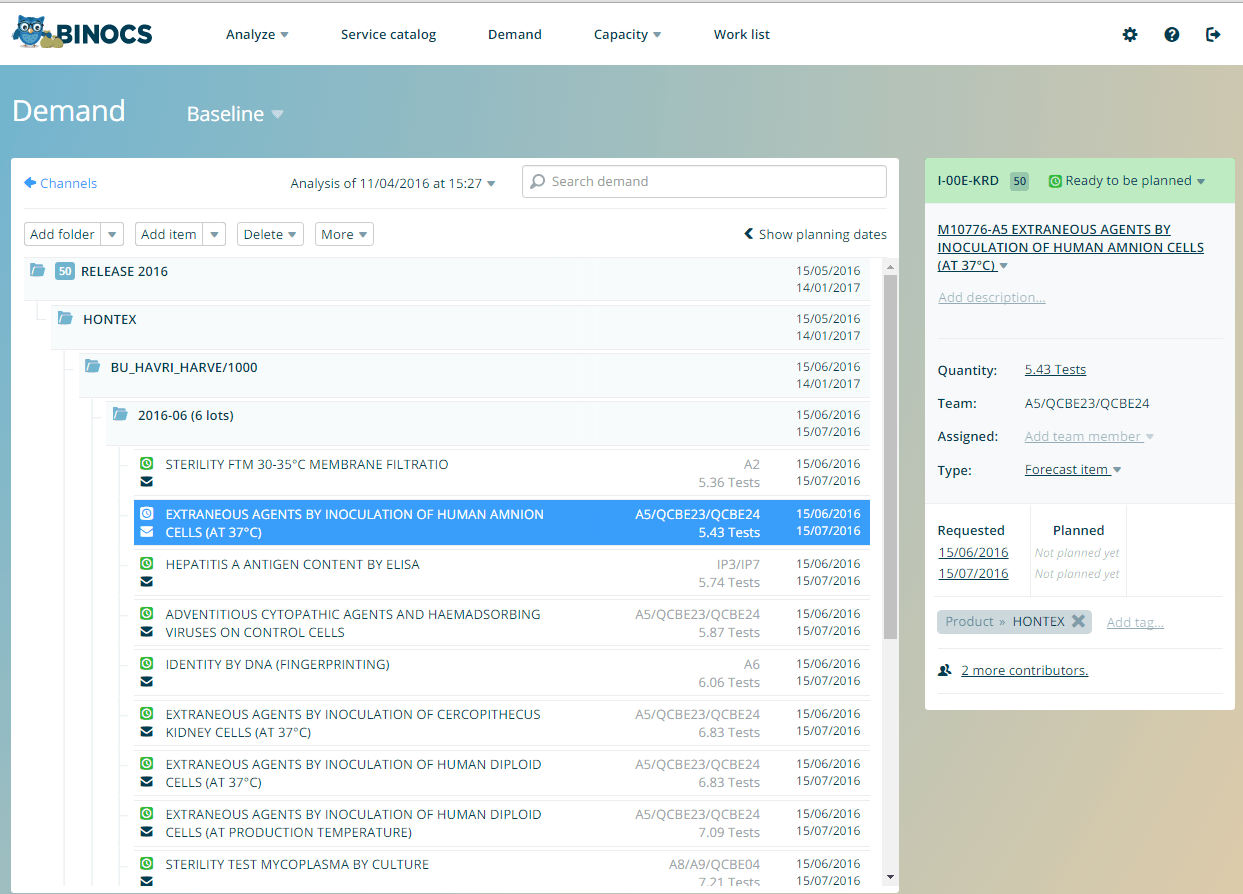

Technician capacity planning in Binocs

The add-on calculates and creates testing demand in Binocs by combining the production plan (in batches) and the inspection plans. The result is that all work created by the technician resource planning for release is nicely structured in Binocs without manual input. The extra info is also used to structure and tag the created demand in Binocs automatically.