Why traditional lean lab tactics are not the sustainable answer

Transforming your lab to a lean laboratory

Transforming your lab to a lean laboratory can result in staggering productivity gains ranging from 20% to 80% and improve your customer service levels drastically.

Many Binocs clients went through a lean lab exercise in the past. More often than not, most of the lean lab tactics get to the background after a while. The main reason, therefore, is that the methodology depends on a counter-intuitive approach and a lot of (external) expertise.

Let the leading resource scheduling tool for laboratories, Binocs, solve this problem. The lean lab comes of-the-shelf. Running Binocs in your labs delivers guaranteed sustainable productivity gains and improved customer service levels in just a fraction of the time.

Let us explain how Binocs does this

Arriving at new Binocs clients that went through a lean lab exercise, we’re always pleased to see

- Standard test methods with correct timings

- Large (magnet) boards for planning and visual management

Two prerequisites to become lean, but in the traditional lean lab approach, the promised gains need to come from specific smart methods and tactics.

- Queuing samples to level demand

- Smart sample grouping methods

- Heuristics such as holding of samples if other labs are not following

- …

But, there are many strategies available. Every lab is a unique combination of workload, volatility, lead-time, equipment, and test types. While following the same basic principles, the exact nature and detail of solutions will vary significantly from lab to lab.

And this is the Achilles heel of the traditional lean lab approach. It depends heavily on counter-intuitive theory and research provided by (external) experts. Lab circumstances change, experts disappear, not well-understood tactics are not used anymore.

Result: lab schedulers spend a lot of time planning and juggling sample sessions by hand to get sub-optimal results.

Lean lab on steroids

Binocs harnasses the full potential of modern computer algorithms. Only digitalizing the magnet board won’t cut it.

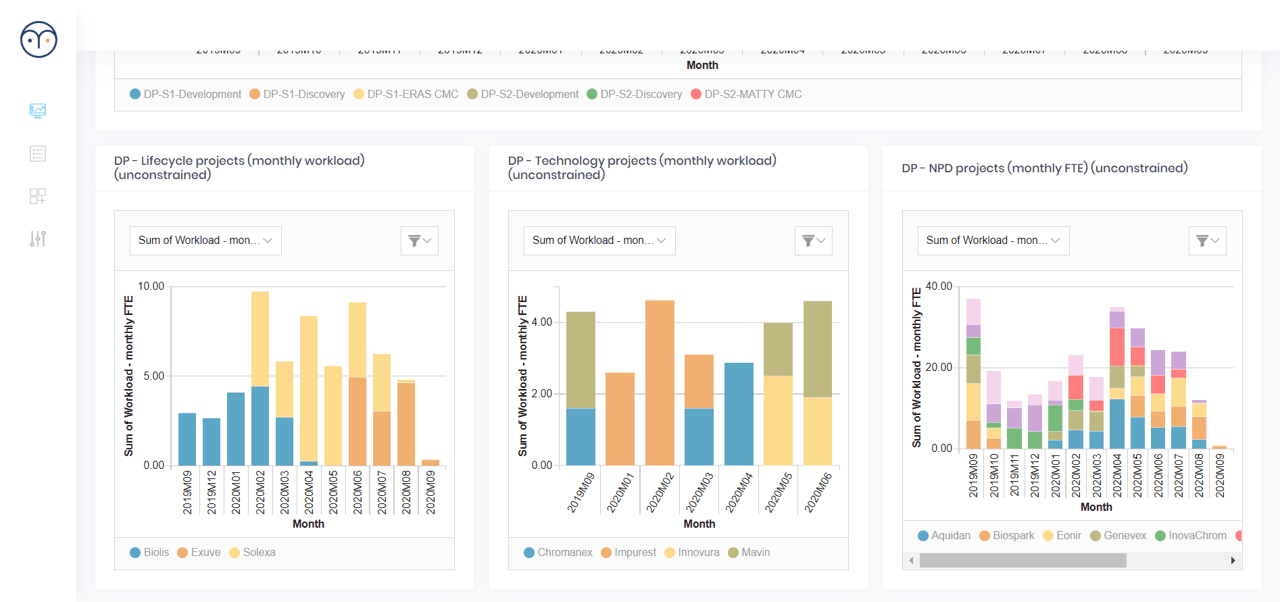

Binocs starts from the same principles: Standard test methods (configured in the system) and a digitalized visual board with the schedule. Using machine learning algorithms, it guarantees sustainable productivity gains and improved customer service level in just a fraction of the time.

You no longer need to rely on experts and time-consuming projects to decide upon the best strategy. The computer automatically calculates the best strategies time and again.

Everything is constantly optimized: from grouping and holding samples to optimizing the schedule based on due dates, priority rules, competences, availabilities, and preferences. No need for people to understand how it’s done because they know they’ll be following the best path possible.

Curious to understand better how Binocs guarantees sustainable productivity gains and improved customer service level? Fill in the form below and request your free demo!

[fc id=’4′][/fc]